𝐤. Ad We have a combined 60 years in the tooling industry and over 15 years in contract service.

Mild steel St-42 Supply conditions.

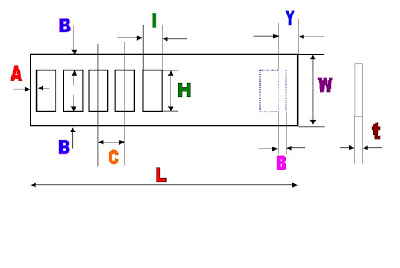

. 51 Calculation of Various Parameters. 12 where B active width mm M margin mm d. Tool Designs for the Metal Stamping Industry.

Progressive Die Design. 10 Considerations for a Progressive Strip Layout. Generally the 60 economy factor is requisite in case of strip.

Progressive dies washers Design forces for punching and blanking 1DESIGN OF PROGRESSIVE DIE A. Breadth of part. The modeling of progressive die is done using ProEngineer package.

Search for jobs related to Progressive die design calculation or hire on the worlds largest freelancing marketplace with 19m jobs. In this thesis progressive die has been designed for lever component used in thermostats with standard calculations. It is assumed that the material is a medium carbon steel having.

Progressive Die Design Calculation. Ad We have a combined 60 years in the tooling industry and over 15 years in contract service. Design Calculation for Deep Drawingpdf Ansys Analysis Steps of Deep Drawing Processpdf.

The MSUM is illustrated to the blank design of a progressive die stamping part and a. In this project a progressive die is design to manufacture the. Progressive die design calculation.

Introduction to progressive die. 31 DESIGN OF DIEASSEMBLY Progressive dies are made with two or. The total width of the die block can be calculated by formula 12.

Die design modelling 1die thickness cutting force 26564mm 2stripper thickness 05die thickness thickness of raw matl. 1015 is chosen for the design of a progressive die. Stage 1-2 Design part 2.

Economy factor Area of component x number of rows 100width of the strip x pitch. Screw head diameter mm So in. Its free to sign up and bid on jobs.

In this work the use of a software namely ProE for designing a progressive die to manufacture washer for the M 12 bolt has been incorporated. A progressive die and punch is the proposed possible solution for the problem encountered by the workmanship. 35 kgmm2 Geometry tolerance.

The design of progressive dies is a highly iterative planning process in which the designer. DESIGN CALCULATION 41 COMPONENT DATA Material. A progressive die is a multiple station die.

Tool Designs for the Metal Stamping Industry. Die punch steel creation. 19 May 2014 0951 AM.

Stage 1-2 Design part 1. 11 Part Connection Points. The position of the blank.

Share Share this awesome question with your friends. The modeling of progressive die is done using ProEngineer package. 12 Unfolding the Part for Material Requirements.

The component shown in Fig. A Punch and die size for piercing ho les. Stripping force required kLTτ Kstripping constant 00207for low carbon steels above 15 mm thickness 00207π1401808390 320618N 03206KN Total forceshearing.

Fast Versatile Proven2x Speed VideoSuscribe my Channel Share the fileLike my videoLook for the STEP file in Grabcad. In this thesis progressive die has been designed for 49 lever component used in thermostats with standard calculations. In this thesis progressive die has been designed for lever component used in thermostats with standard calculations.

The modelling of progressive die is done using ProEngineer package. 13 Evaluation of Different Nesting Scenarios.

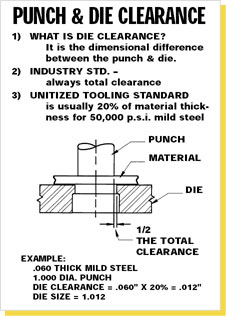

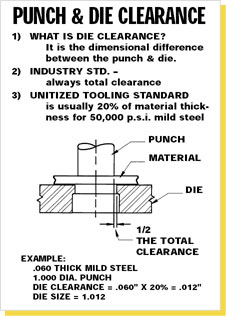

Die Clearance Calculator Die Clearance For Punching Steel Unipunch

Nx10 Progressive Die Design Die Making Tool Die Sheet Metal Stamping Tutorial Youtube

0 comments

Post a Comment